The Ultrasonics Lab researches in the interface between engineering, physics, medicine and computational mechanics to create new fundamental knowledge and applied concepts and technologies to advance clinical and industrial elastography, diagnostic and therapeutic ultrasound.

The lab was founded 2004, and since 2021 is labelled as Singular Laboratory, physically occupies two spaces, 110 m2 at the Polytechnic building, and 30 m2 at the Hospital Universitario Clinico San Cecilio. It is also labelled as the PAIDI TEP959 and IBS TEC-12 research grouops, and is part of the Excellence Scientific Unit MNAT.

The projects below are examples of how Engineering can help Medical Science: by understanding and using the mechanics of tissue making use of ultrasound - mechanical waves whose interaction with tissue embraces many secrets.

Novel elastography biomarkers: viscosity and nonlinearity. Clinical application to melanoma diagnosis.

The adoption of multiscale approaches by the biomechanical community has caused a major improvement in quality in the mechanical characterization of soft tissues. The recent developments in elastography techniques are enabling in vivo and non-invasive quantification of tissues mechanical properties. Elastic changes in a tissue are associated with a broad spectrum of pathologies, which stems from the tissue microstructure, histology and biochemistry. This knowledge is combined with research evidence to provide a powerful diagnostic range of highly prevalent pathologies, from birth and labor disorders (prematurity, induction failures, etc.), to solid tumors (e.g., prostate, cervix, breast, melanoma) and liver fibrosis, just to name a few. We strive to elucidate the potential of viscous and nonlinear elastic parameters as diagnostic mechanical biomarkers. First, by providing an insight into the classic role of soft tissue microstructure in linear elasticity; secondly, by understanding how viscosity and nonlinearity could enhance the current diagnosis in elastography; and finally, by clinically testing the technology at the Ultrasonics Lab space at Hospital Universitario Clinico San Cecilio.

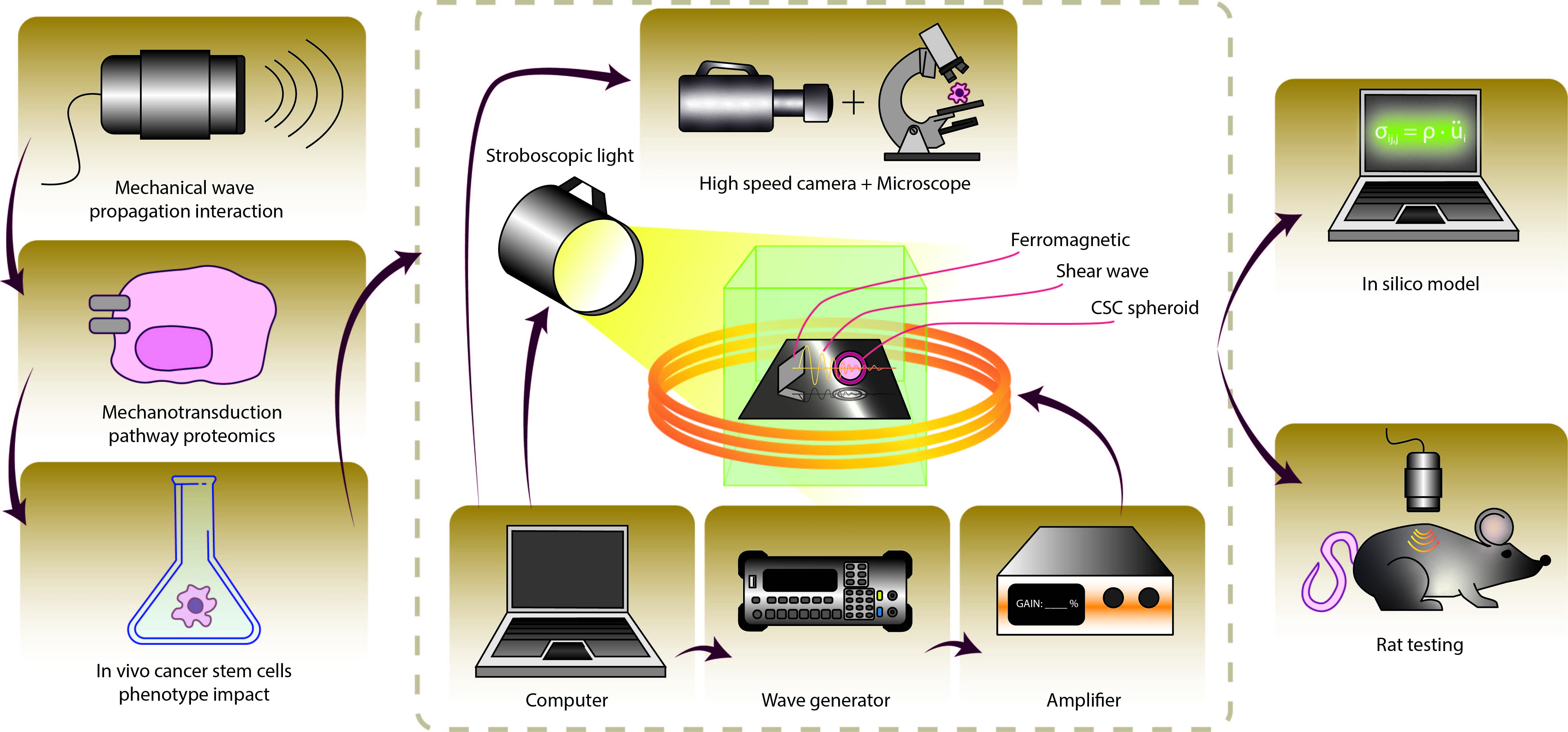

Mecanotherapy: Impacting cancer cell phenotype via mechanical waves to fight cancer

The mechanical microenvironment of cancer cells is recently being highlighted as a key controller of their progression and fate, but the understanding of how mechanical forces affect cell behaviour and therefore tumour progression has been very restricted. Research on how technologies such as mechano-transduction contribute to maintaining cell homeostasis has not fully emerged, as it has been mostly limited only to direct forces applied to cells. The MECHANOTHERAPY project operates on the disruptive proposal of creating the basis to generate controlled shear mechanical waves to induce therapeutic effects remotely on a wide range of tumoroids. If successful, the project will transform cancer treatment, opening a completely non-invasive new way of fighting tumours to be combined with existing methods for their optimization, contributing to the way we prevent and treat cancer.

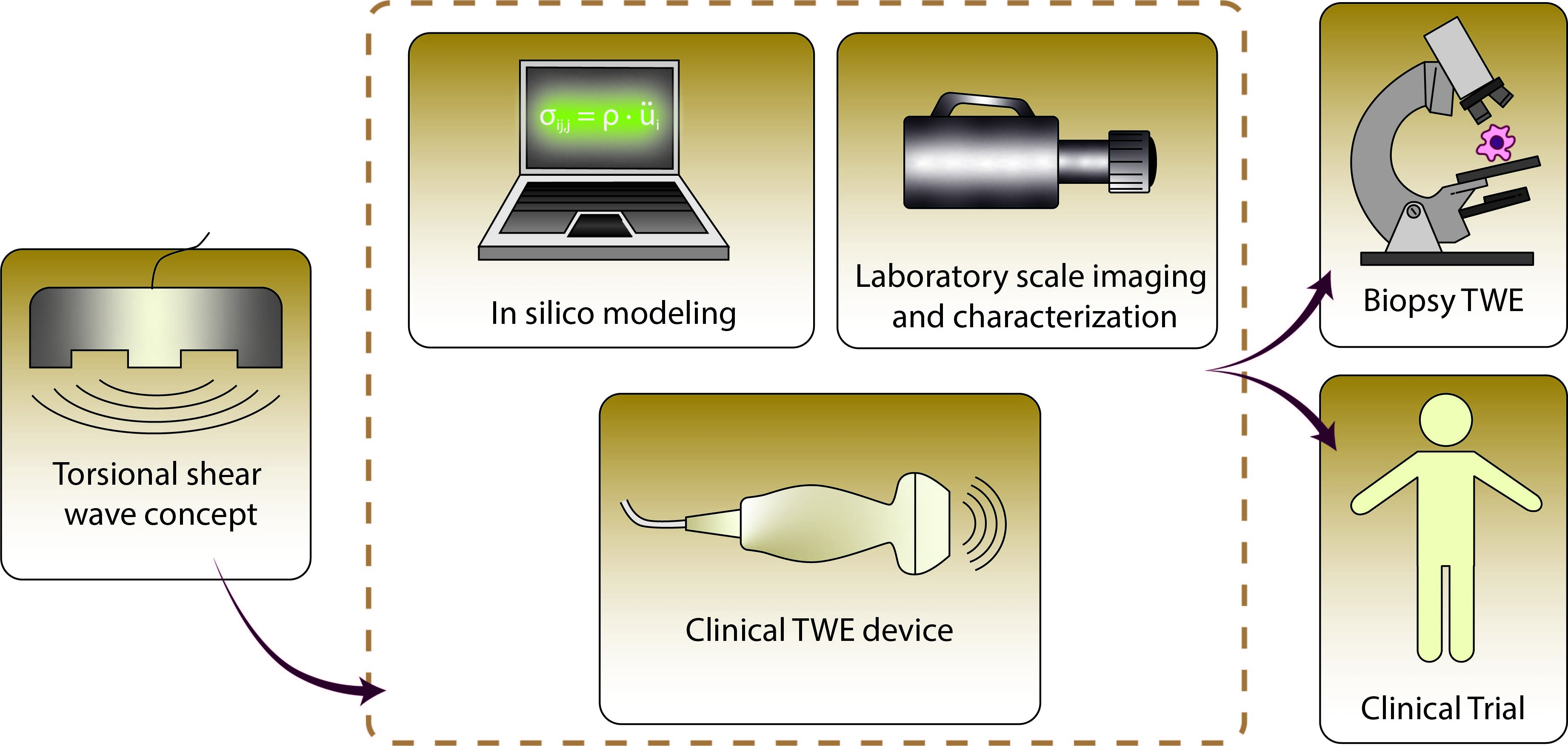

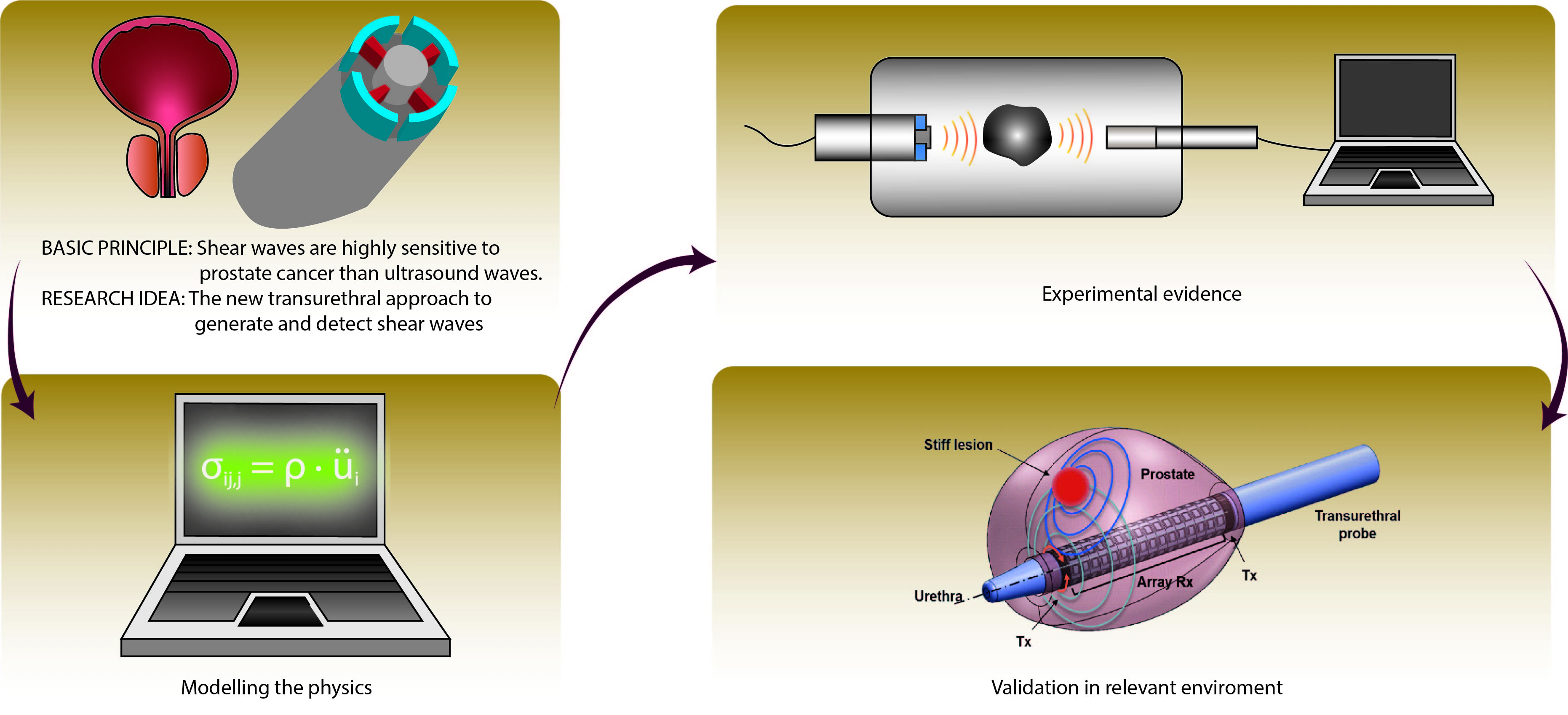

UROELAST: Prostate cancer elastography

The UROELAST project focuses on the prototyping of a transurethral catheter to perform transluminal torsional wave elastography for the screening and diagnosis of prostate cancer. The concept stems from the collaboration of the Ultrasonics Lab - UGR with the Ultrasonics Lab - UCL (University College London); and the fusion of the concepts of torsion wave and mechanical biomarkers towards the global objective of diagnosing prostate cancer.

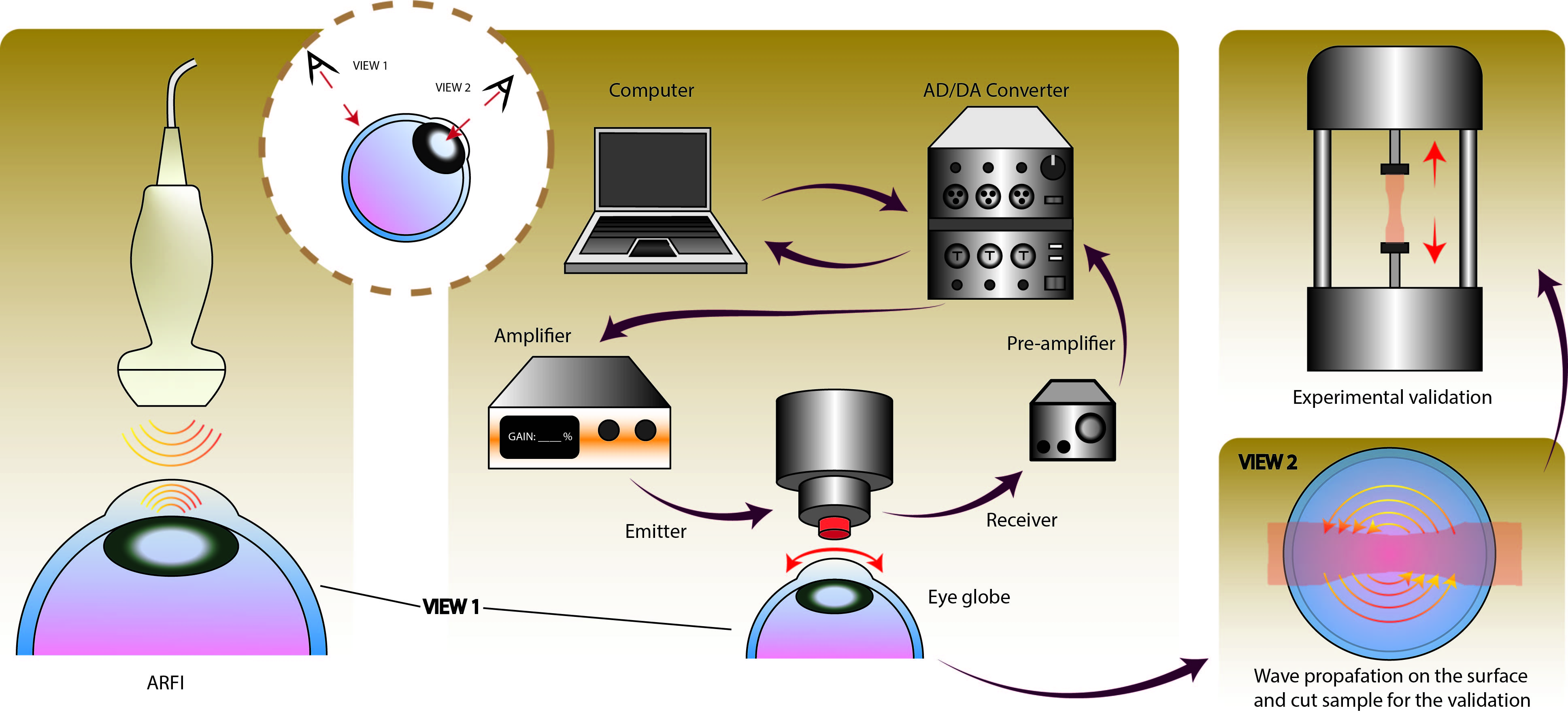

Corneal elastography by torsional waves

Corneal mechanical changes are believed to occur before any visible structural alterations observed during routine clinical screening. We propose developing torsional waves elastographu (TWE) adapted to the specificities of the cornea. By measuring the displacements in the propagation plane perpendicular to the axis of the emitter, the effect of guided waves in plate-like media was proven negligible. Ex vivo experiments were carried out on porcine corneal samples considering a group of control and one group of alkali burn treatment (NH4OH) that modified the mechanical properties, establishing a predictive capacity of damage and intraocular pressure (IOP), paving the way for future in vivo studies.

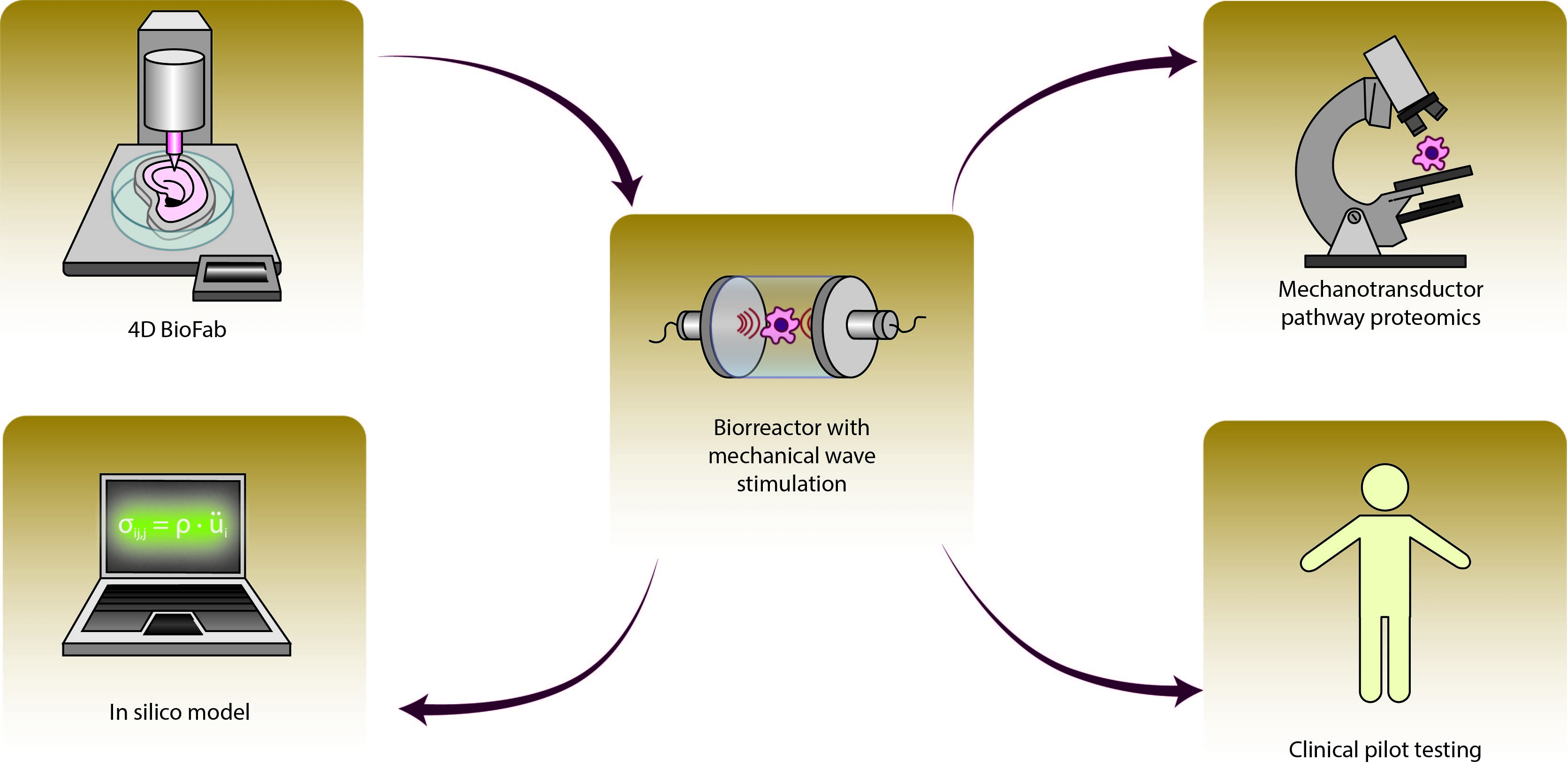

4D biofabrication: mechanical stimulation of artificial tissue grafts

We conceive and prototype biorreactors that generate mechanical waves to mechanotransduce growth and differentiation capabilities to artificial tissue.

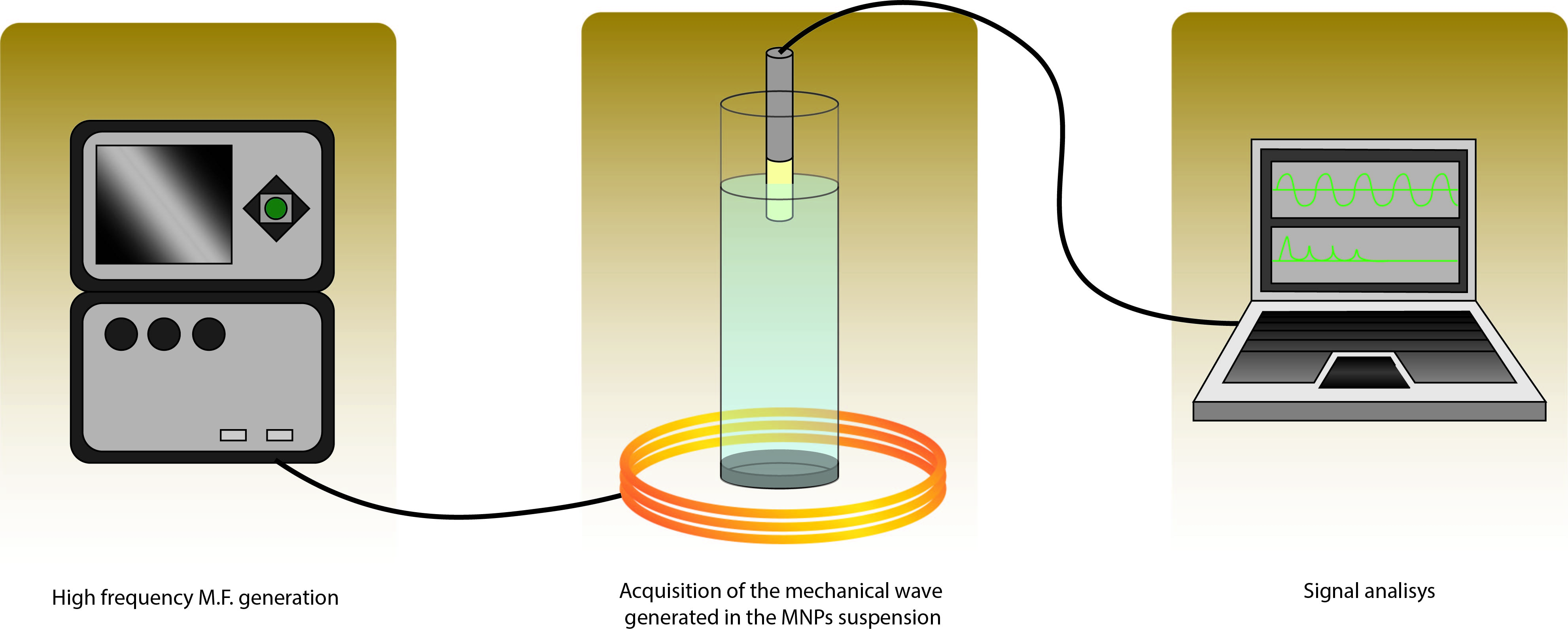

Ultrasonic-Magnetic nanoparticles for medical imaging

Interdisciplinary work carried out by the Ultrasonics Lab. and the Institute of Nanoscience and Materials of Aragon (INMA). The magnetic hyperthermia in magnetic nanoparticles (MNP) has developed several questions in the past years. The cell damage caused by MNPs facing an alternating magnetic field cannot be explained only in terms of heat increment but a mechanical phenomenon is expected to be enhancing the process. The combination of experience and equipment of both groups is driving the research of this topic to new milestones. A setup combining the application and reading of acoustical signals, and a high frequency magnetic field generation equipment has been developed by the Ultrasonics group. Computational models of the experiments are also carried out by the team to support the empirical results. The definition of these physical mechanism which connects the magnetic and mechanical behavior of a nanomaterial can open a new area of working and researching.

Major equipment and capabilities

- Ultrafast echography: 1 Verasonics Vantage 256 HIFU and 1 Verasonics Vantage 256 High Frequency, with both medical and industrial transducers.

- 3 dynamic tensile testing machines with video deformation measurement and biocompatibility capabilities.

- 10+ 3D printers and bioprinters, including Stratasys Objet Prime 30, FDM, resin, Regemat 3D V1, with a resolution down to 14 microns.

- Advanced laboratory purpose advanced ultrasonic equipments.

- 2 ultrasonic scanners (up to 100MHz, 50 microns, 14 bits).

- Portable echnography systems and industral ultrasound systems, ranging kHz to 100MHz, with various techniques, from pulse-echo, transmission, nonlienar mixing, P, S, Rayleigh, guided waves, torsional waves, etc.

- Ultrasound sensor prototyping facilities for industrial and medical applications.

- Biorreactor prototyping facilities for industrial and medical applications.

- CPU and GPU servers, owned.